High-Speed Stator Winding Machines

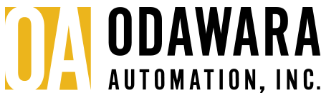

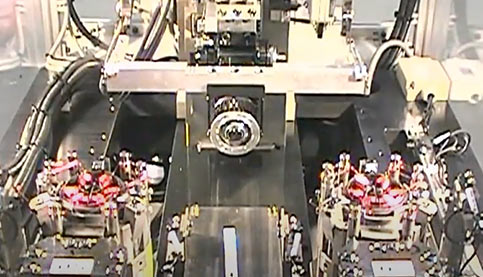

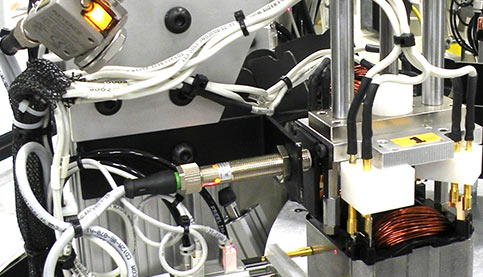

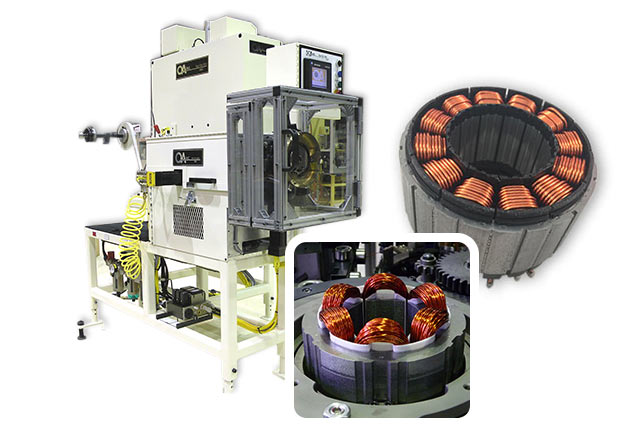

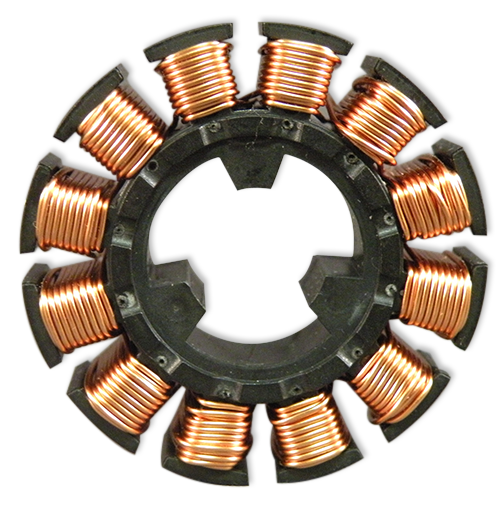

Our needle winding machines are high-speed stator winders. The High Speed SPW series uses fixed or oscillating needles and a vertical spindle that allows for either square track or elliptical needle paths, allowing for higher fills and improved winding. The IOW series can be configured for: multi-needle – open core/flat winding; dual head dual needle – coil winding outer, inner or segment; and single head – coil winding outer or inner.

- The Most Advanced Technology

- Efficient & Precise Winding

- Superior After-Sales Service

| Wire AWG: | 17 – 27 |

|---|---|

| Stack Height: | 10 – 100mm |

| Number of Slots: | Any |

| Core | OD 60 – 300mm | ID 20 – 200mm |

| Number of Axes: | 3 – 4 |

These are typical product sizes. The capability of the machines to manufacture each stator depends on a number of factors including end turn dimensions, winding pattern, bus bar design, etc. Please contact an Odawara sales representative with your unique requirements.

| Automobiles | HEV drive & generator, radiator cooling fan, ABS/EESC, EPS, various pumps, etc. |

|---|---|

| Household Electrical Appliances | Air conditioner, refrigerator, vacuum cleaner, washing machine, juicer, mixer, etc. |

| Industry, Medical Equipment | Power tool, generator, MRI, various pumps, etc. |

| Industry, Medical Equipment AO/AV Equipment | Printer, copy, fax, HDD, DVD/CD, etc. |

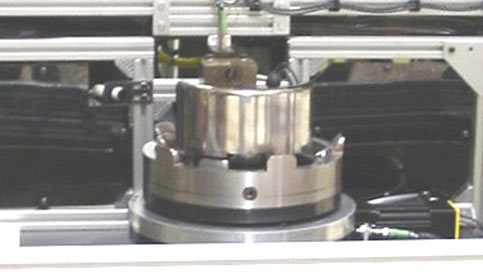

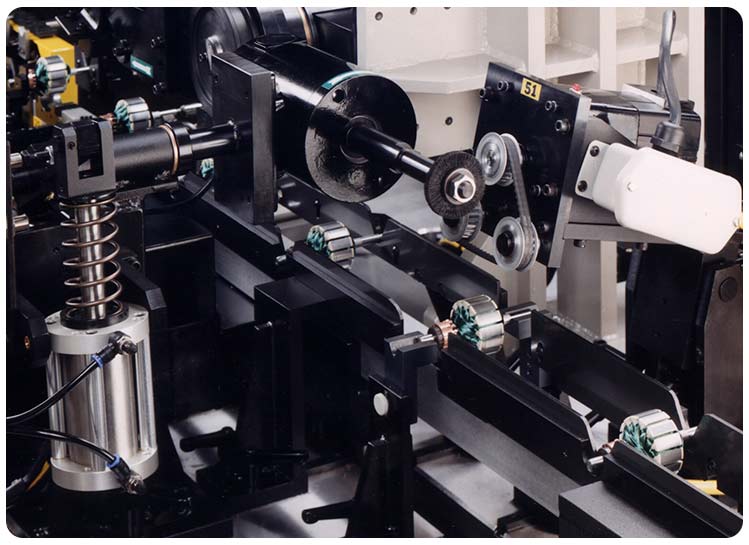

Typical Stator BLDC Line Structure

Automation and Material Handling

Increase efficiency even further with automation and material handling solutions by Odawara Automation. Our services include:

- Material Handling

- Dunnage Load/Unload

- Automated Machine Load/Unload

- Robotic Systems

- Test Equipment

- Part Transfer Systems: Conveyors and Transfer Pallets

- Vision/Inspection Systems

- Quality System Integration: Manufacturing Operating Systems (MOS) and Manufacturing Engineering Systems (MES)