Making Machines to Make Motors

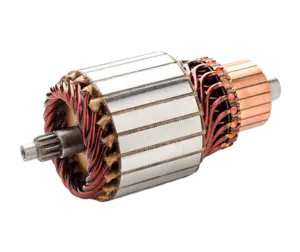

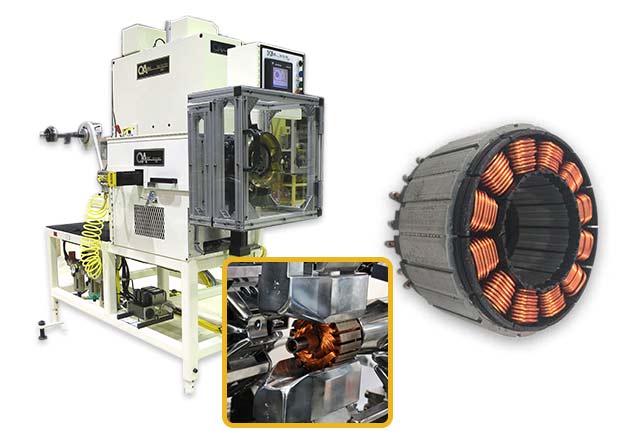

At Odawara Automation, we provide high-speed winding systems for almost every motor production need. Our engineering team is consistently developing the most advanced and revolutionary winding technologies to help our customers push production numbers even higher. When you need precision, quality, and automation, turn to Odawara — your single-source solution.

FAQs on Odawara Automation’s Electric Motor Winding Solutions

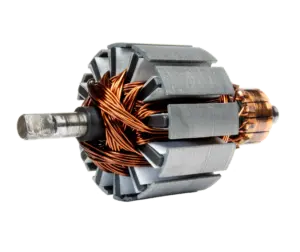

This is dependent on the wing process, but we have wound parts as small as half an inch in diameter up to parts 12 inches in diameter. Size isn’t our limiting factor. Odawara is happy to look at any design and provide a winding feasibility assessment.

Odawara likes to work in the 32 AWG to 16 wire diameter range, but we have gone smaller and larger. We will work with you to find a solution that works best for your production needs. We also can work with rectangular-shaped wire.

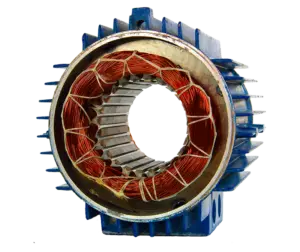

Yes, Odawara offers Design For Manufacturing services. OA’s goal is to help customers design a motor that is capable of being mass-produced with automated and semi-automated equipment.

Odawara will perform a winding feasibility assessment on any designs you send to OA for review. If we see minor issues, we’ll provide feedback on how to make improvements. If there are major issues, we will provide a quote for a Design For Manufacturing study with the goal to produce a design that can be mass-produced.

Odawara offers a range of equipment, from a stand-alone machine that does one operation to fully automated hands-off systems. We work with you to optimize the manufacturing process to meet your needs and budget.

The cost of a winding solution varies as it is dependent on what is the best fit for your production needs. We have worked on projects that have ranged from $100,000 to $8 million+. Once we have designs in hand, whether you provide or utilize our DFM services, we then provide you with a winding feasibility study with detailed costs.