Heavy Duty Insertion Winding Machines

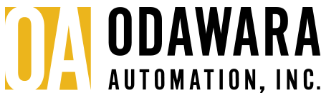

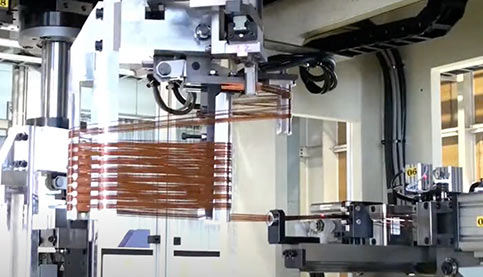

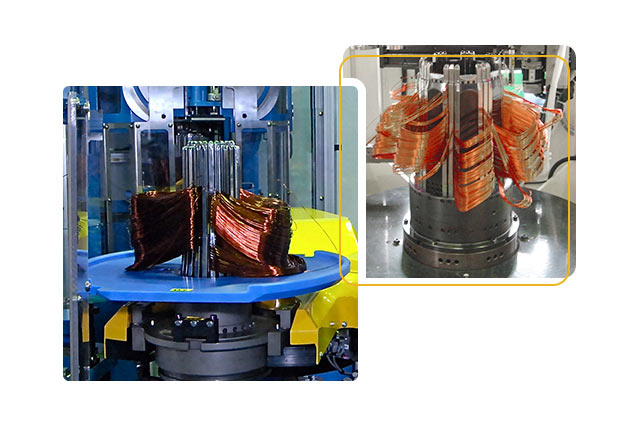

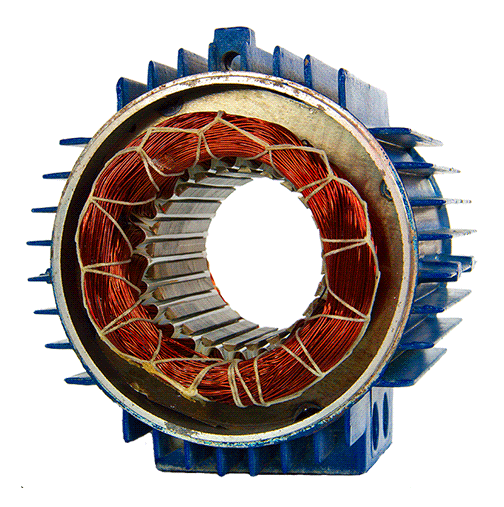

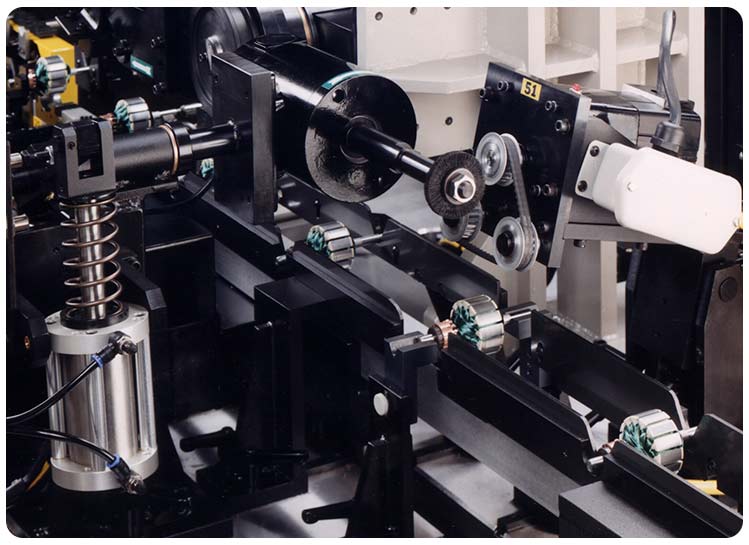

The ZET and SCW winding machines are high-speed, stator coil winders for two- and four-pole induction motor winding. The machines are capable of winding multiple wires in hand with special features for wire grippers and dereeler depending on wire size. Combining winding and coil/wedge insertion is an option in many machine configurations. Coil insertion and winding is driven by an AC servo motor and ball screws for a smooth operation.

- Reliable Construction

- Efficient & Precise

- Superior After-Sales Service

| Stator ID: | 110 – 150mm |

|---|---|

| Stator OD: | 175 – 230mm |

| Wire In Hands: | 10 – 20, (depending on # of layers on winding former, # of turns, and wire diameter) |

| Lead Length | 300 – 600mm |

| Main Axis Number of Rotation | Stock Winding – 400 rpm Winding – 300 – 600 rpm |

| Wire Dia | 0.5 – 1.2mm |

These are typical product sizes. The capability of the machines to manufacture each stator depends on a number of factors including end turn dimensions, winding pattern, bus bar design, etc. Please contact an Odawara sales representative with your unique requirements.

| Automobiles | EV/HEV drive & generator, EPS, air conditioner, etc. |

|---|---|

| Household Electrical Appliances | Air conditioner, refrigerator, washing machine, various fans, etc. |

| Industry, Medical Equipment | Machine tool, robot, generator, forklift, construction machine, etc. |

Typical Insertion Line Structure

Automation and Material Handling

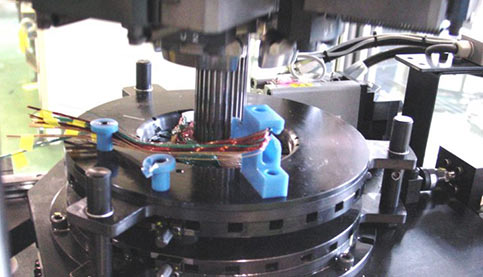

Increase efficiency even further with automation and material handling solutions by Odawara Automation. Our services include:

- Material Handling

- Dunnage Load/Unload

- Automated Machine Load/Unload

- Robotic Systems

- Test Equipment

- Part Transfer Systems: Conveyors and Transfer Pallets

- Vision/Inspection Systems

- Quality System Integration: Manufacturing Operating Systems (MOS) and Manufacturing Engineering Systems (MES)