Solutions for R&D to High Volume Lines

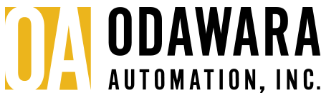

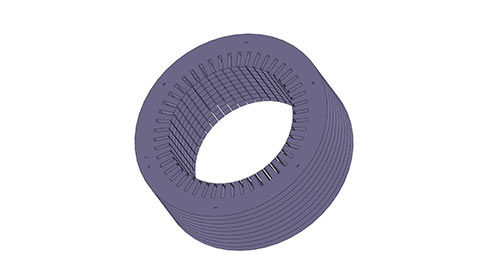

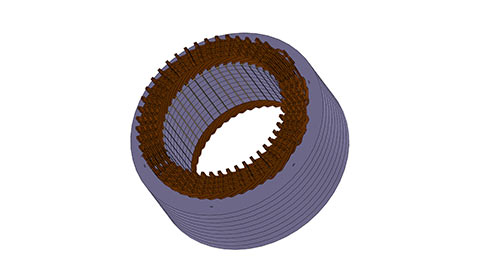

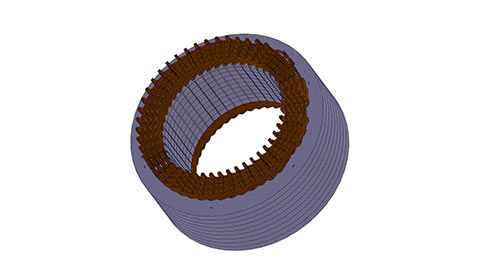

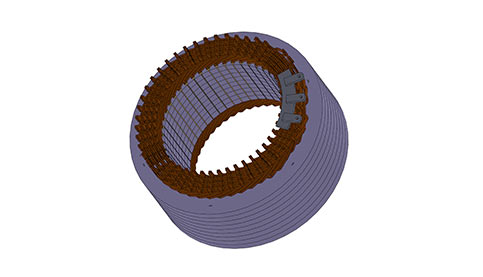

Odawara offers multiple hairpin winding solutions to meet all customer needs from R&D scale machines through to high volume manufacturing lines. Complexity in the stator design can be managed through the utilization of different coil forming, alignment, and insertion processes.

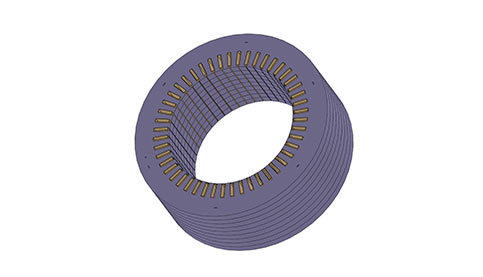

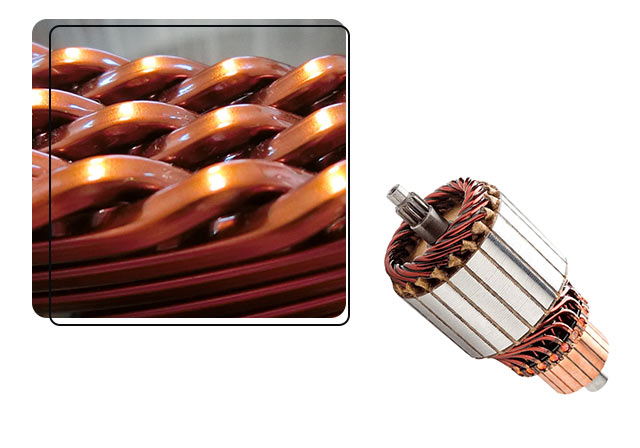

Insulation paper is formed to U, S, or B shape per stator design and inserted to each slot. Hairpin coils are formed and enamel is removed mechanically or by laser. Coils are aligned per customer winding pattern and inserted simultaneously. Coils are twisted using Odawara’s proprietary technology, allowing for minimal end turn heights. Coil ends are welded per customer requirements using laser or TIG welding technologies.

Odawara offers fully automated and semi-automated systems. Modular technologies are used that allow for scalability and flexibility.

Additional capabilities can be included per customer requests including:

- Laser part etching

- In line part inspection

- Electrical testing

| Stator OD | 160 – 300 mm |

|---|---|

| Stator ID | 100 – 250 mm |

| Stator Height | 35 – 200 mm |

| Number of Slots | Any |

| Number of Layers | 2 – 10 |

| Wire Dimensions | Up to 6.5 x 4.5 mm |

These are typical product sizes. The capability of the machines to manufacture each stator depends on a number of factors including end turn dimensions, winding pattern, bus bar design, etc. Please contact an Odawara sales representative with your unique requirements.

| Automobiles | EV Motor Drive/Generator, EV Motor Drive, ISG, Alternator |

|---|

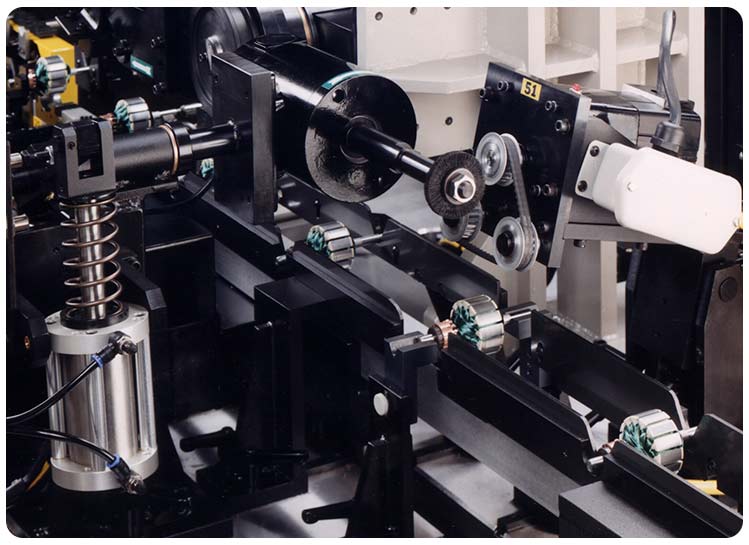

Typical Line Structure

Automation and Material Handling

Increase efficiency even further with automation and material handling solutions by Odawara Automation. Our services include:

- Material Handling

- Dunnage Load/Unload

- Automated Machine Load/Unload

- Robotic Systems

- Test Equipment

- Part Transfer Systems: Conveyors and Transfer Pallets

- Vision/Inspection Systems

- Quality System Integration: Manufacturing Operating Systems (MOS) and Manufacturing Engineering Systems (MES)