Winding Machines for Round or Rectangular Wire

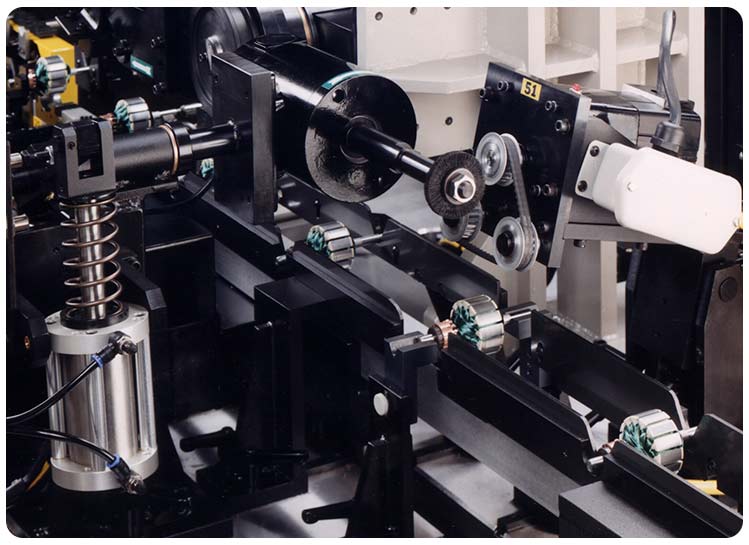

Odawara offers segment winding solutions for both round and rectangular wire, along with for low volume/R&D production through to high volume manufacturing. Individual processing cells for each step are available as are fully integrated, automated lines.

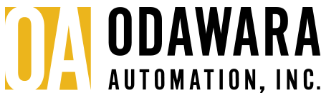

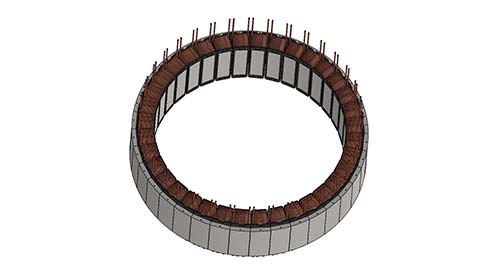

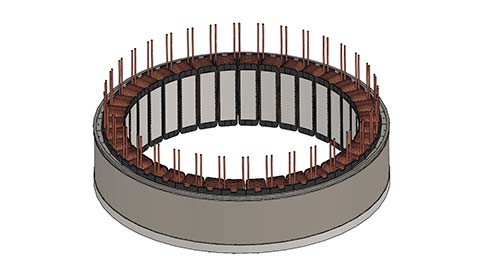

Individual segments are fixtured and rotated to precisely layer magnet wire per customer requirements. Wound segments are aligned and pre-assembled in the required circular orientation, after which the bus bar is placed.

Enamel is removed and lead wires are routed to the necessary position and cut to length in the lead processing step. Lead wires are welded to the bus bar per customer requirements. Welded segment assemblies are placed in the stator housing and secured in place by shrink fitting.

Additional capabilities can be included per customer requests, including:

- Laser Part Etching

- In-line Part Inspection

- Electrical Testing, Individual Segments or Full Assemblies

| Wire AWG: | 24 – 17 |

|---|---|

| Maximum Stack Height: | 0.5 – 4” |

| Number of Winding Heads: | 2 – 4 |

These are typical product sizes. The capability of the machines to manufacture each stator depends on a number of factors including end turn dimensions, winding pattern, bus bar design, etc. Please contact an Odawara sales representative with your unique requirements.

| Automobiles | HEV drive & generator, EPS, Various pump, etc. |

|---|---|

| Industrial, Medical Equipment | Servo motor, etc. |

Typical Stator BLDC Line Structure

Automation and Material Handling

Increase efficiency even further with automation and material handling solutions by Odawara Automation. Our services include:

- Material Handling

- Dunnage Load/Unload

- Automated Machine Load/Unload

- Robotic Systems

- Test Equipment

- Part Transfer Systems: Conveyors and Transfer Pallets

- Vision/Inspection Systems

- Quality System Integration: Manufacturing Operating Systems (MOS) and Manufacturing Engineering Systems (MES)