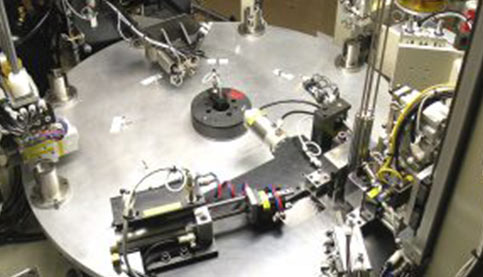

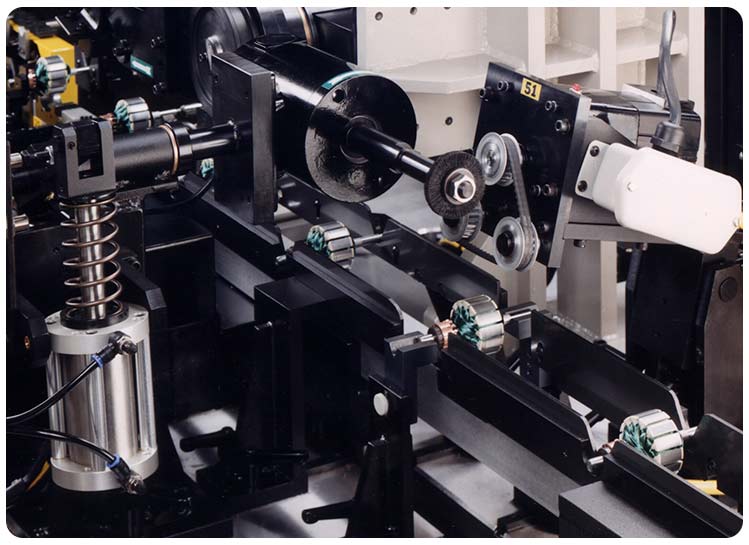

Advanced Flyer Winding Machines

The DAW is Odawara’s most advanced armature winding machine, designed for universal two-pole armatures. It provides tooling flexibility; fast, efficient, accurate winding; improved wire termination; user-friendly programming; and easy setup and adjustment with a tool-less changeover.

- Tooling Flexibility

- Fast & Accurate Winding

- User-Friendly Programming

- Superior After-Sales Service

| Wire AWG: | 17 – 35 |

|---|---|

| Maximum Stack Length: | 100mm |

| Maximum Stack Dia.: | 70mm |

| Maximum Commutator Dia.: | 35mm |

| Maximum Flyer Speed (1:1 pulley ratio) | 3000rpm |

These are typical product sizes. The capability of the machines to manufacture each stator depends on a number of factors including end turn dimensions, winding pattern, bus bar design, etc. Please contact an Odawara sales representative with your unique requirements.

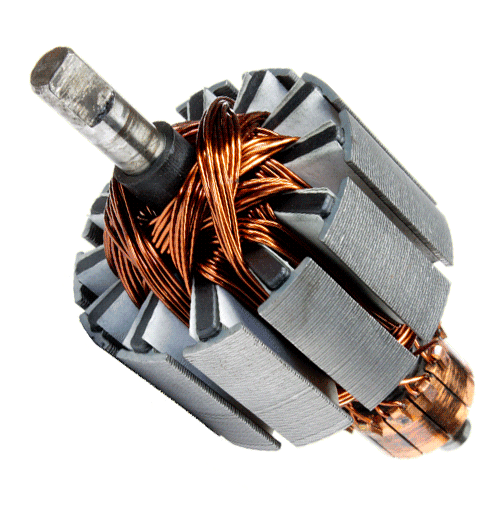

Products Manufactured with Flyer Winding Machine Technology

Flyer winding machines are used to wind wire onto armatures and coils with precision and efficiency. This technology is essential in manufacturing electric motors and components found in a wide range of products across the automotive, home appliance, industrial and office equipment sectors. Through our advanced winding solutions, manufacturers have increased production, enhanced quality and achieved greater automation.

See the graph below for examples of products with an electric motor commonly manufactured with flyer winding technology.

| Automobiles | Windshield wiper, power window, blower, radiator cooling fan, EPS, ABS/ ESC, etc. |

|---|---|

| Household Electrical Appliances | Vacuum cleaner, washing machine, juicer, mixer, shaver, dryer, etc. |

| Industry, Medical Equipment | Power tool, robot, pump, etc. |

| OA/AV Equipment | Printer, copy, fax, HDD, DVD/CD, etc. |

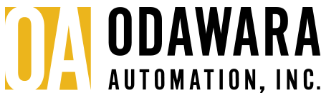

Typical Armature Line Structure

Automation and Material Handling

Increase efficiency even further with automation and material handling solutions by Odawara Automation. Our services include:

- Material Handling

- Dunnage Load/Unload

- Automated Machine Load/Unload

- Robotic Systems

- Test Equipment

- Part Transfer Systems: Conveyors and Transfer Pallets

- Vision/Inspection Systems

- Quality System Integration: Manufacturing Operating Systems (MOS) and Manufacturing Engineering Systems (MES)