Artificial intelligence (AI) has substantially evolved over the years. Since Chat-GPT launched, numerous other AI software, such as Claude, Google Bard, Microsoft Copilot, and more, have been released. AI is “technology that enables computers and machines to simulate human intelligence and problem-solving capabilities.” ¹ Artificial Intelligence can be further broken down into sub-divisions, which include machine learning, neural network, deep learning, natural language processing, cognitive computing, and computer Vision ².

Computer Vision, which “uses machine learning and neural networks to teach computers and systems to derive meaningful information from digital images, videos, and other visual inputs – and to make recommendations or take actions when they see defects or issues,” ³ has become an important option on many Odawara machines. There are many applications in which one might incorporate AI and Vision into their processes. Taking a closer look at how Odawara Automation has integrated Vision technology into their machines.

Enhancing Process Control with Vision Technology at Odawara Automation

Odawara Automation (OA) has incorporated Artificial Intelligence and Vision into its machines for years for many reasons. However, we will focus on why Odawara uses Vision for process control. Before AI and Vision, industries used sensors or relied on their operators to monitor the process. With Vision installed, it can check different features simultaneously, significantly decreasing cycle time by days, even weeks. Vision systems quickly capture and analyze photos to determine correct manufacturing, operating faster than the human eye.

Examining how Vision contributes to process control is essential for understanding its impact. At Odawara Automation, we use Vision to check a part’s orientation, whether we stripped wire enamel or not, whether we completed welded connections and more. Engineers program the computer’s software with images that define good and bad outcomes. For example, the two photos above depict if the wires were bent into the correct position. Vision is checking if the automated machine performed the task accurately on the part to reduce the chances of manufacturing a deficient part. As more photos are taken and parts are processed during the training phase, the AI can change the red/green boundary. It learns what wire locations produced good parts and adjusts accordingly. Another application of Vision is scanning a pre-applied barcode for a part number.

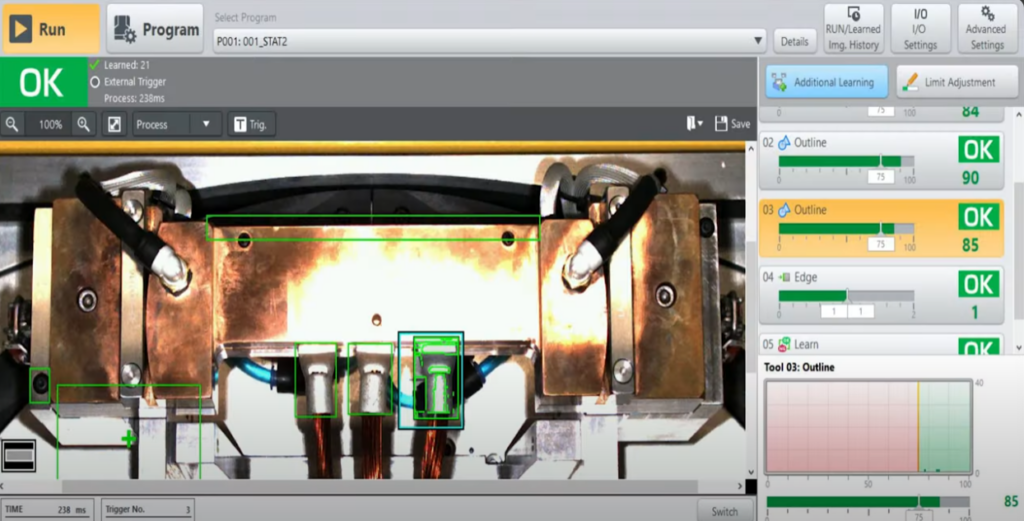

In the photo below, the camera checks if the lugs are in the correct terminal and orientation. It also checks if the correct tooling has been loaded into the machine and if the tooling loaded correctly. This can all be done with just one photo. All these applications of using Vision for process control help produce consistent parts, increase production, improve quality, and reduce cost.

The Advantages of AI and Vision Integration

There are numerous benefits to using AI and Vision in the system. One of the most significant advantages of incorporating Vision into the process is its user-friendly nature. This means that it will be easy for customers to adapt once the machine is delivered. The cost of installation is also not too high, making it a cost-effective solution. Moreover, the ease of implementation of Vision is a key factor in its appeal. Over the years, Vision has become faster to integrate into software. Additionally, incorporating Vision helps mitigate issues related to low-skilled operators, reducing human error.

-

-

-

-

-

-

-

-

-

-

- User-friendly

- Cost-effective

- Easy for customers to adjust

- Faster to implement

- Marginal cost is not too high

- Help deals with low-quality operators

-

-

-

-

-

-

-

-

-

The Growth and Development of AI and Vision

Artificial intelligence and Vision have significantly evolved over the last five to ten years. As technology advances, AI’s simplicity of use, prevalence, and accuracy continue to increase. As AI continues to develop, software accuracy continues to improve. For instance, upgrades to the camera’s hardware have increased its capability, allowing machine builders to measure features they never used to be able to during production. The enhancements to AI and Vision in the past decade cement its value for the future.

Artificial Intelligence has made significant strides in recent years, with various applications like Computer Vision transforming industries. Odawara Automation’s integration of AI and Vision systems into its machines demonstrates the technology’s potential to enhance process control, improve quality, and increase efficiency. As AI and Vision evolve, they become increasingly valuable tools for manufacturers and businesses across sectors.

-

“What Is Artificial Intelligence (AI)? | IBM,” n.d., https://www.ibm.com/topics/artificial-intelligence.

-

“6 Major Sub-Fields of Artificial Intelligence | Medium,” n.d., https://rancholabs.medium.com/6-major-sub-fields-of-artificial-intelligence-77f6a5b28109

-

“What Is Computer Vision? | IBM,” n.d., https://www.ibm.com/topics/computer-vision.