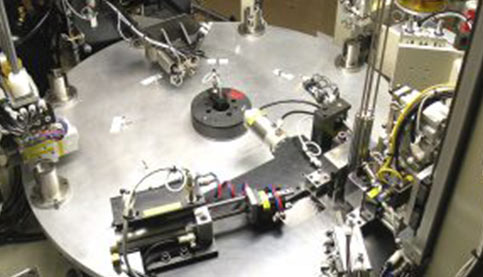

Advanced Flyer Winding Machines

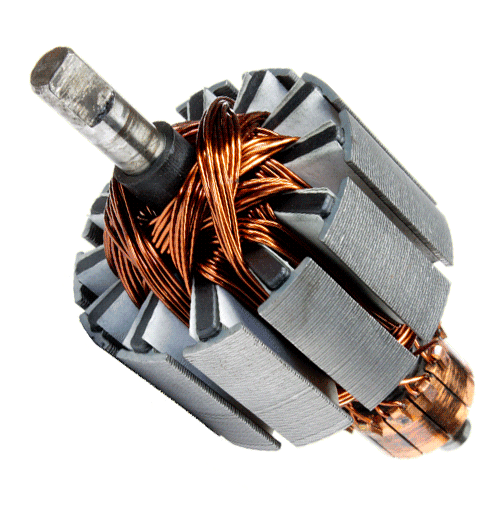

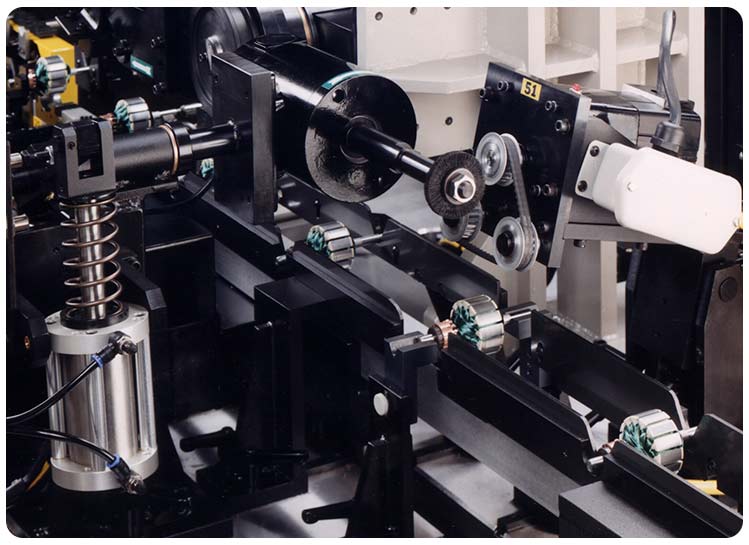

The DAW is Odawara’s most advanced armature winder, designed for universal two-pole armatures. It provides tooling flexibility; fast, efficient, accurate winding; improved wire termination; user-friendly programming; and easy setup and adjustment with a tool-less changeover.

- Tooling Flexibility

- Fast & Accurate Winding

- User-Friendly Programming

- Superior After-Sales Service

| Wire AWG: | 17 – 35 |

|---|---|

| Maximum Stack Length: | 100mm |

| Maximum Stack Dia.: | 70mm |

| Maximum Commutator Dia.: | 35mm |

| Maximum Flyer Speed (1:1 pulley ratio) | 3000rpm |

These are typical product sizes. The capability of the machines to manufacture each stator depends on a number of factors including end turn dimensions, winding pattern, bus bar design, etc. Please contact an Odawara sales representative with your unique requirements.

Products Using a Flyer Winding Machine

| Automobiles | Windshield wiper, power window, blower, radiator cooling fan, EPS, ABS/ ESC, etc. |

|---|---|

| Household Electrical Appliances | Vacuum cleaner, washing machine, juicer, mixer, shaver, dryer, etc. |

| Industry, Medical Equipment | Power tool, robot, pump, etc. |

| OA/AV Equipment | Printer, copy, fax, HDD, DVD/CD, etc. |

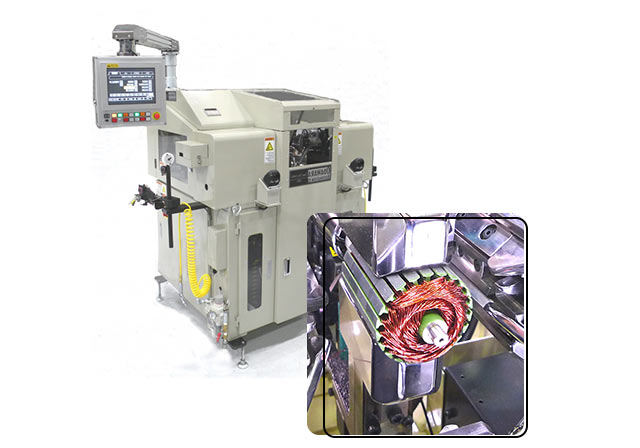

Typical Armature Line Structure

Automation and Material Handling

Increase efficiency even further with automation and material handling solutions by Odawara Automation. Our services include:

- Material Handling

- Dunnage Load/Unload

- Automated Machine Load/Unload

- Robotic Systems

- Test Equipment

- Part Transfer Systems: Conveyors and Transfer Pallets

- Vision/Inspection Systems

- Quality System Integration: Manufacturing Operating Systems (MOS) and Manufacturing Engineering Systems (MES)