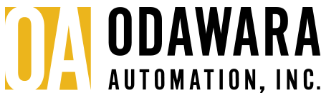

Various industries rely on electric motors, considering them vital components for numerous appliances. Coil winding is the primary process in making an electric motor. The winding of an armature or stator will depend on the type of motor. The concentrated winding of BLDC stators is accomplished with needle winding. Continue reading below to learn how Odawara’s IOW and SPW winders compare.

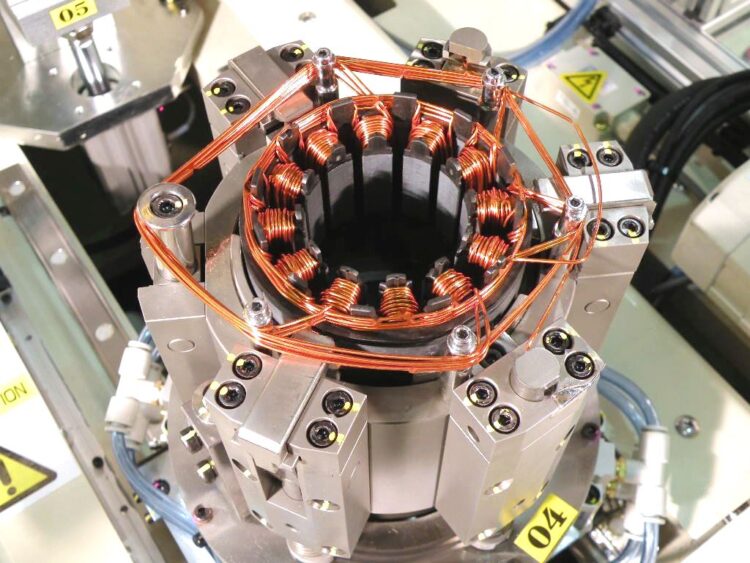

The IOW Series

The IOW Series can wind inside or outside slotted stators and segments using a single needle. The winding process is controlled by servo motors, ensuring precise positioning along all axis positions. The servo controls provide the IOW machines with flexibility for winding different stators. Typically, the start and finish leads are on the same side as the inter-pole leads, meaning the machine can pull and hook the inter-pole leads around end molds or stud pins outside the part chuck. The single needle and servo controls make the IOW a very flexible machine.

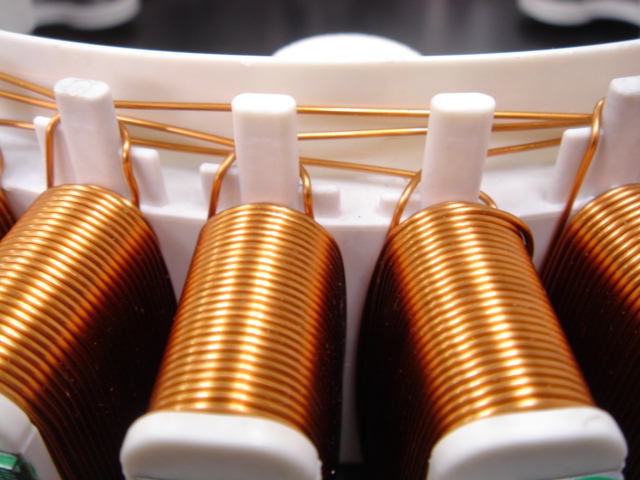

The SPW Series

The SPW Series is designed to wind inside slotted stators with 1, 2, or 3 needles. This type of needle winding uses oscillating needles and a vertical spindle that allows for a square track or elliptical needle paths, allowing for higher fills and improved winding. A cam motion located under the tooling fixture drives the winding spindle. The start and finish leads are on the opposite side from the inter-pole leads. The multiple needles and cam motion allow for a much faster winding speed compared to the IOW. In addition, SPWs are flexible for stack height, wire size, and turns per coil because the high-speed cam motion suits high-volume production.

In conclusion, coil winding serves a vital role in the manufacture of electric motors. It is essential to understand the specific requirements of each winding type. As explained above, the IOW Series and the SPW Series offer distinct advantages in needle winding. The IOW Series excels in its ability to wind both inside and outside slotted stators and segments with precise control via servo motors. On the other hand, the SPW Series, tailored for inside slotted stators, employs multiple needles and cam motion for faster winding while allowing adaptability for stack height, wire size, and turns per coil. These technologies represent the cutting edge of stator winding, contributing to the manufacturing efficiency of producing electric motors across industries.